'KICK THE TYRES'

Andrew van Ryneveld, from Spitfire SA Boat Trailers, passes on some salient advice on looking after your trailer.

You’re stuck on the side of the road in the middle of nowhere. You’ve lost both wheels on one side of your trailer and your boat has just missed becoming a writeoff! Think it won’t happen to you? Think again.

Basic trailer maintenance is essential for all boaties. While reams of information on this exists, here’s a reminder of key points. First and foremost, do not wait until next summer to check your trailer. How you put it away after using it over summer is key to being able to enjoy it for the next season!

WASHING YOUR TRAILER

Washing your trailer after saltwater use is always a good idea, regardless of whether it’s steel, galvanised, or alloy. This is because salt water is an electrolyte solution containing more dissolved ions than fresh water, which enables electrons to move more easily and bring forward corrosion more quickly in salt water than it does in fresh.

Trailer washing systems, such as the Spitfire ‘Spitwash’ system, can significantly assist this rinsing process by also facilitating consistent and efficient water jetting onto to critical components.

YOUR BRAKES

Braked trailers have either a cable or hydraulic braking system. Cable brakes are simple to maintain and a good squirt of a lubricant on the mechanisms after each trailer use, plus a periodic greasing of the tow-ball piston, will often suffice. The big issue with cable brakes is that the cables stretch over time. We regularly come across trailers with little or no braking; some owners admit they’ve never adjusted the brakes. Please check and re-tension the cables regularly.

Spitfire’s Spitwash system will keep your trailer in good nick

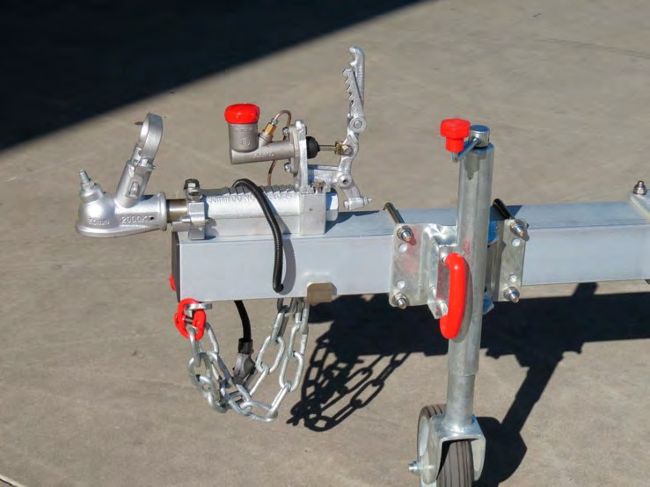

It makes sense to keep an eye on hydraulic brake oil reservoirs

Hydraulic brakes are more efficient and apply significantly more braking force. While these systems are more suited to heavier braked trailers, they are very well suited to any braked trailer due to their consistency in operation. Earlier types of hydraulic brake callipers were prone to calliper piston lock-up, but more recent callipers are available with stainless steel pistons instead of traditional phenolic plastic pistons (looks like a like a brown bakelite). Lock-up is caused by swelling of the piston, which causes the piston to seize in the calliper cylinder.

Hydraulic brake systems require the brake fluid level to be maintained. It should be topped up to avoid allowing air to enter the brake circuit, which will result in ineffective braking until the system can be re-bled.

Check your brake pad wear. If you use your trailer regularly and travel significant distances, a trailer fitted with stainless steel brake discs will be much friendlier to your brake pads. Pads that pair with rusty brake discs fundamentally clean the discs before braking occurs. This process exacerbates pad wear and reduces braking efficiency.

LIGHTS

A set of good quality submersible trailer lights is so convenient, but many people are concerned about water ingress despite many advances in technology – especially LED. Lights that haven’t leaked after a first few immersions are unlikely to be leakers! Lights showing signs of leakage should be inspected and changed.

Checks on the trailer plug and also any in-line connections are strongly recommended. The trailer plug needs to be free of damage, dirt, and grime, and a regular squirt of CRC and a brush with an old toothbrush will be sufficient to maintain good contact.

NUTS AND BOLTS CHECK

Boat trailers travelling at 100km/h over bouncy roads suffer many induced stresses in key components through flexing movement. And movement can cause loosening of nuts and bolts. All trailers use bolts and nuts to fasten critical items such as the wheels, axles, leaf springs, etc. On a regular basis any critical nuts and bolts should be checked – and nothing is more important than to make sure your trailer wheel nuts are properly tightened.

Always check your winch cable or strap for wear

Submersible lights need regular inspection

WINCH AND WEBBING OR ROPE

Winches are used as one of the primary devices to secure the boat to the trailer during travelling, launching, and retrieving. A regular check of the entire length of spooling rope or webbing is absolutely necessary, and any fraying or wear and tear observed must be repaired at the earliest opportunity.

BEARINGS

One maintenance item stands out above all others…. your wheel bearings. When there is an unexpected failure, you’ll be lucky if you still have options for convenient repairs to be done!

We recommend that every boat owner needs to self-inform about what is inside the hub – the quality and condition of the grease, what seals are used, and how to read indications that there could be a problem emerging. Boaties are encouraged to check bearings yearly. An excellent time to do this is after the season ends. Any water ingress that has occurred will quietly destroy your bearings during layup.

Bearings fail through lack of inadequate lubrication. Be sure that there is sufficient grease in your hubs and do not rely on your Bearing Buddy to grease your bearings properly!